Best Practices for Displaying Forklift Vehicle Security Check In Industrial and Storehouse Settings

The execution of effective forklift vehicle safety signs is essential in commercial and warehouse settings, where the risk of mishaps can significantly influence both personnel and operations. Trick considerations such as presence, placement methods, and adherence to governing standards are crucial for making best use of the efficiency of these indicators. Additionally, the continuous upkeep and periodic analysis of signage can additionally boost safety actions - Forklift Truck Safety Signs. However, the genuine challenge hinges on stabilizing these components to promote not just compliance but additionally a proactive society of safety. What certain strategies can companies take on to ensure their safety and security signage absolutely serves its objective?

Relevance of Safety And Security Signs

The value of security signage in atmospheres where forklift trucks operate can not be overemphasized, as these indicators play an essential role in preventing crashes and making certain the security of workers. Effective safety and security signs acts as a vital interaction device, conveying important details regarding prospective risks connected with forklift procedures. This consists of warnings regarding pedestrian zones, rate restrictions, and marked forklift courses, which are crucial for maintaining an arranged and secure working atmosphere.

Appropriately displayed safety signs can boost situational understanding among employees, advising them of the risks associated with their surroundings. They provide clear guidelines on risk-free practices, such as putting on proper individual safety tools (PPE) and sticking to operational standards. Safety and security signage adds to compliance with regulative requirements, assisting organizations prevent fines and promote a society of safety and security.

Along with their preventative duty, security signs foster a feeling of liability among workers. When workers know safety and security procedures and the possible consequences of ignoring them, they are more probable to take aggressive steps to secure themselves and their coworkers. Investing in high-grade safety signs is crucial for any workplace where forklift trucks are in operation.

Secret Exposure Aspects

Efficient exposure is vital in guaranteeing the security of both forklift operators and pedestrians in busy work environments. To achieve this, several key visibility factors have to be taken into consideration when making and positioning safety and security indications.

First, the size and font of the text on the indicator play a critical duty. Bigger typefaces boost readability from a distance, allowing individuals to quickly understand the message. In addition, using vibrant and clear fonts can dramatically boost clarity under different lighting problems.

Reliable Placement Methods

Sign positioning dramatically impacts their efficiency in connecting safety and security messages within forklift procedures. To optimize exposure and understanding, indicators need to be strategically positioned in areas where forklift task is widespread. Key places consist of crossways, unseen areas, and near loading and dumping areas, where drivers and pedestrians interact often.

Height is another crucial factor; indicators here need to be placed at eye degree to ensure they are conveniently seen by both forklift drivers and ground employees. In addition, making use of contrasting colors and clear graphics will boost presence, particularly in low-light conditions or high-traffic locations.

Take into consideration the circulation of traffic when determining positioning. Indications ought to be placed to assist operators securely and effectively through the work space, decreasing the danger of accidents. In addition, routine assessments must be conducted to make certain that indications remain unhampered by equipment or supply, as moving formats can reduce their effectiveness.

Incorporating responses from employees relating to sign placement can additionally result in renovations. Engaging personnel in this procedure fosters a society of safety and security and awareness, eventually adding to a more safe and secure work atmosphere. By applying these effective placement methods, companies can improve interaction and adherence to safety procedures.

Conformity With Laws

Making sure compliance with policies is vital for preserving a risk-free working environment in forklift operations. Regulative bodies such as the Occupational Security and Health Management (OSHA) and the American National Requirement Institute (ANSI) develop standards that determine the appropriate use security indications. Adherence to these policies not only promotes safety and security however also mitigates the risk of penalties and legal liabilities.

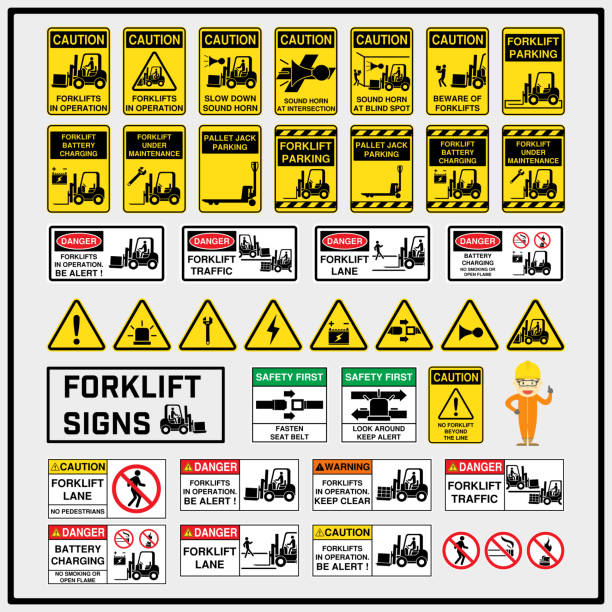

Forklift safety signs must be plainly noticeable, clear, and tactically placed according to regulatory needs. These indications should make use of standard icons and shade codes to share critical information properly. As an example, yellow suggests care, while red signals risk, guaranteeing that workers can swiftly interpret the check in high-stress scenarios.

Organizations must perform regular audits to verify that all safety signage satisfies present legal requirements. By making sure that forklift safety and security signs adhere to mandated guidelines, companies foster a culture of safety awareness among employees, thereby enhancing overall workplace safety and productivity.

Routine Maintenance and Updates

Keeping and updating forklift safety indicators is vital for guaranteeing that they remain reliable and appropriate in the workplace. Normal evaluations should be carried out to evaluate the problem of security indicators, as direct exposure to harsh commercial environments can result in fading, damage, or obsolescence. Indications that are no much longer understandable or that include out-of-date info can considerably threaten safety methods.

It is vital to develop a routine upkeep timetable that includes examining the visibility and clearness of all safety and security signage. Any type of indicators that are used, harmed, or misaligned should be quickly changed or repositioned to maintain their efficiency. Additionally, as policies and security criteria evolve, it is crucial to upgrade signage to reflect present techniques and compliance requirements.

Engaging staff members in safety and security training sessions can also strengthen look here the relevance of maintaining and updating security indicators. This not only makes certain that everyone is conscious learn this here now of the indications' definitions but likewise promotes a culture of safety and security within the office. By prioritizing regular maintenance and updates, organizations can create a safer atmosphere and improve the general effectiveness of their forklift security signage.

Final Thought

In final thought, the application of finest methods for showing forklift truck security indications is necessary for improving work environment security in industrial and storehouse atmospheres. By prioritizing visibility, employing effective positioning approaches, making certain conformity with guidelines, and dedicating to regular upkeep, companies can dramatically minimize the danger of accidents. Such measures not only connect dangers successfully yet likewise promote a culture of safety and security that profits all workers included in forklift operations.